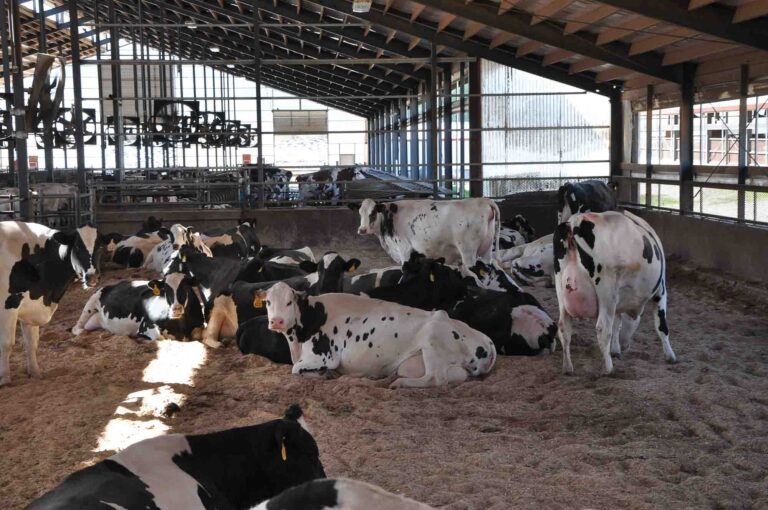

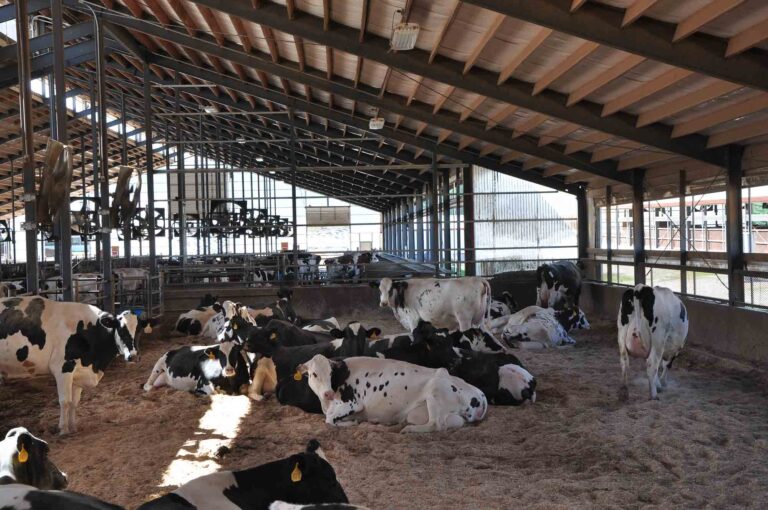

Animal Bedding

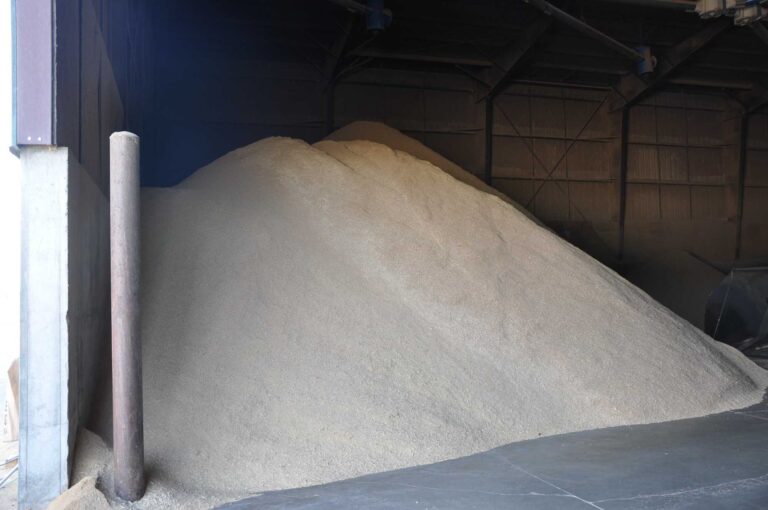

The sawdust is blown into trailers at the Mills not from ground piles. The sawdust is then unloaded from the trailers into a Grinder for uniform size and passed through three magnets to remove any foreign material, then into building for storage until needed for drying.

The material is sent through a triple pass drying system, where the sawdust is dried to 10% moisture at temperatures of 1200 to 1300 degrees to kill bacteria. Our sawdust is tested at the University of Minnesota for Udder Health and has been found to be very clean with “incredibly low” bacterial counts.

From the dryer the material is blown into trailers, no ground contact for contamination, from there ready for delivery. We have a constant supply of sawdust available all year long.